Double Bag Packing is a modern and efficient solution designed to meet the growing demands of precision, speed, and quality in today’s packaging industry. By offering enhanced versatility and cost-effectiveness, this method is quickly becoming the preferred choice for manufacturers across various industries.

What is Double Bag Packing?

Double Bag Packing utilizes advanced technology to fill and seal two pouches simultaneously. This innovative approach not only increases production speed but also ensures precise portioning and airtight sealing, making it suitable for a wide range of products, from food items to industrial goods.

The RZ8-170S Double Bag Filling Sealing Machine is at the forefront of this technology, offering unmatched performance and efficiency.

Why Choose Double Bag Packing?

1.High-Speed Production

The RZ8-170S Double Bag Packing Machine can achieve speeds of up to 130 bags per minute, making it ideal for high-volume production lines. Its ability to handle two bags simultaneously greatly enhances throughput.

2.Enhanced Versatility

●Suitable for various product types, including powders, granules, liquids, and semi-solids.

●Compatible with a wide range of pre-made pouch sizes and designs.

3.Cost and Material Efficiency

●The non-filling and non-sealing system ensures no product or packaging material is wasted if the pouch isn’t fully opened.

●Reusable pouches further reduce material costs.

4.Superior Sealing Quality

Double bag packing guarantees airtight seals, preserving the freshness and integrity of products while enhancing their shelf appeal.

5.User-Friendly and Automated

●Equipped with an intuitive PLC and HMI touch screen, making operation simple and efficient.

●Fully automated processes, including weighing, filling, sealing, and alarming systems, reduce the need for manual intervention.

6.Hygienic and Reliable

●All contact parts are made of SUS304 stainless steel, ensuring safety and sanitation.

●Imported tolerance plastic bearings require no refueling, reducing maintenance and contamination risks.

Applications of Double Bag Packing

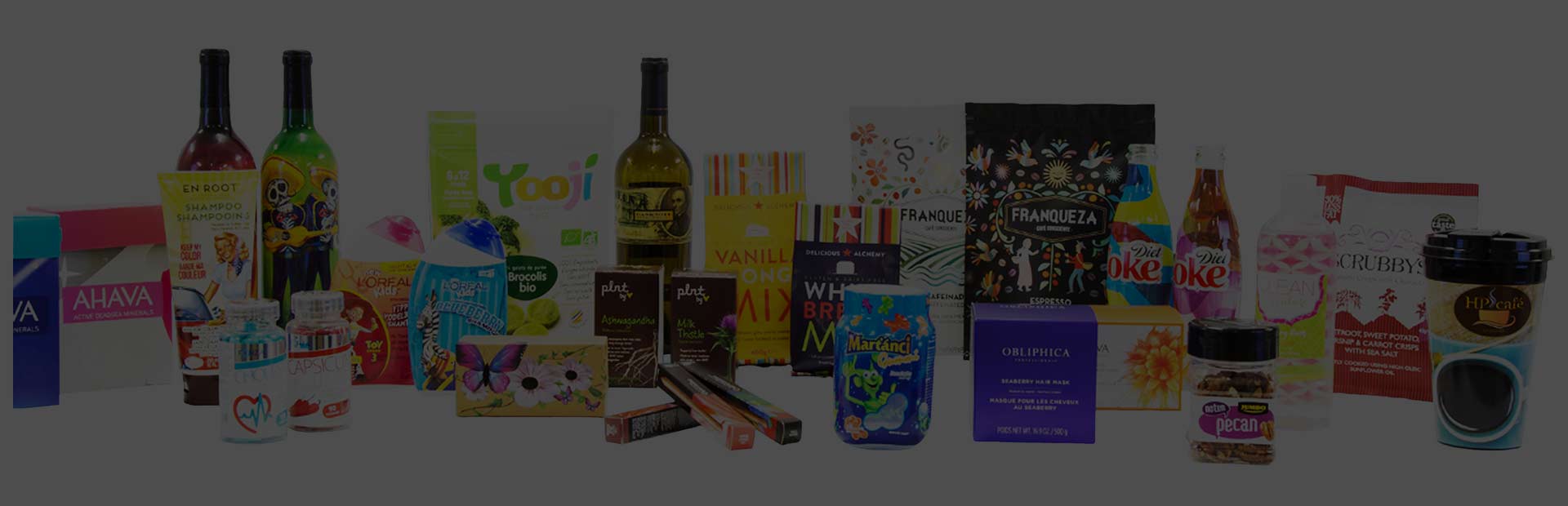

Double Bag Packing is widely used in industries such as:

●Food and Beverages: Melting chocolate, coffee, sugar, nuts, snacks.

●Pharmaceuticals: Powders, granules, and other medicinal products.

●Daily Necessities: Liquid soaps, detergents, and other household goods.

The flexibility of the RZ8-170S allows it to cater to these diverse needs while maintaining high precision and quality.

Case Study: Melting Chocolate Packaging

In a recent application, the RZ8-170S Double Bag Packing Machine was used to package melting chocolate. The machine, integrated with a multi-head linear weigher, delivered precise portioning and high-speed production.

With features such as pouch cleaning, non-filling alarms, and automated sealing, the machine ensured minimal waste and top-notch sealing quality, resulting in visually appealing and airtight packages.

Benefits of Double Bag Packing

●Improved Efficiency: Faster production speeds and precise filling reduce downtime and increase output.

●Cost Savings: Material efficiency and automated processes lower production costs.

●Enhanced Product Quality: Airtight seals and precise portioning ensure products maintain freshness and consistency.

Conclusion

Double Bag Packing is a game-changing solution for manufacturers seeking to optimize their packaging processes. The RZ8-170S Double Bag Filling Sealing Machine embodies the best of this technology, delivering speed, precision, and versatility.

Whether you’re packaging food, liquids, or daily necessities, Double Bag Packing ensures your products are sealed to perfection while meeting the highest standards of efficiency and quality.