Capacity

Up To 120 BPM

Filling Volume

5-5000g

Bag Width

55-390mm

Bag Length

≤550mm

For weighing filling various products automatically in all kinds of premade pouches

Max speed to 100 bags/min

Bag width from 55mm to 400mm with different models

| Bag Width Range | 50-120 mm | Weight | 2500 kg |

| Bag Length Range | 80-370 mm | Total power | 5.41 kw |

| Filling Range | ≤ 500g | Compress air | ≥ 0.4 m³/min |

| Max Speed | ≤ 130 bags/min | Dimensions | 1850 mm*2360 mm*1550 mm |

| Bag Width Range | 100-220 mm | Weight | 1800 kg |

| Bag Length Range | 150-370 mm | Total power | 9.47 kw |

| Filling Range | ≤ 1000g | Compress air | ≥ 0.4 m³/min |

| Max Speed | ≤ 45 bags/min | Dimensions | 1950 mm*1720 mm*2420 mm |

| Bag Width Range | 60-160 mm | Weight | 1450 kg |

| Bag Length Range | 80-370 mm | Total power | 3.22 kw |

| Filling Range | ≤ 500g | Compress air | ≥ 0.5 m³/min |

| Max Speed | ≤ 100 bags/min | Dimensions | 1840 mm*1610 mm*1550 mm |

| Bag Width Range | 80-220 mm | Weight | 1800 kg |

| Bag Length Range | 100-370 mm | Total power | 3.42 kw |

| Filling Range | ≤ 1500g | Compress air | ≥ 0.4 m³/min |

| Max Speed | ≤ 60 bags/min | Dimensions | 1950 mm*1740 mm*1550 mm |

| Bag Width Range | 80-240 mm | Weight | 1500 kg |

| Bag Length Range | 150-370 mm | Total power | 3.02 kw |

| Filling weight | ≤ 1500g | Compress air | ≥ 0.4 m³/min |

| Max Speed | ≤ 60 bags/min | Dimensions | 1860 mm*1520 mm*1550 mm |

| Bag Width Range | 90-250 mm | Weight | 2700 kg |

| Bag Length Range | 150-370 mm | Total power | 4 kw |

| Filling Range | ≤ 2500g | Compress air | ≥ 0.4 m³/min |

| Max Speed | ≤ 60 bags/min | Dimensions | 2200 mm*2050 mm*2000 mm |

| Bag Width Range | 180-300 mm | Weight | 1800 kg |

| Bag Length Range | 150-450 mm | Total power | 3.62 kw |

| Filling weight | ≤ 2500 g | Compress air | ≥ 0.4 m³/min |

| Max Speed | ≤ 50 bags/min | Dimensions | 2080 mm*1720 mm*1650mm |

| Bag Width Range | 85-170 mm | Weight | 3000 kg |

| Bag Length Range | 150-330 mm | Total power | 5.41 kw |

| Filling Range | ≤ 1000g | Compress air | ≥ 0.4 m³/min |

| Max Speed | ≤ 100 bags/min | Dimensions | 2320 mm*2060 mm*1650mm |

| Bag Width Range | 270-400 mm | Weight | 2500 kg |

| Bag Length Range | 150-600 mm | Total power | 3.62 kw |

| Filling Range | ≤ 5000g | Compress air | ≥ 0.4 m³/min |

| Max Speed | ≤ 30 bags/min | Dimensions | 2150 mm*2020 mm*1700 mm |

| Bag Width Range | 80-190 mm | Weight | 2000 kg |

| Bag Length Range | 80-370 mm | Total power | 6.27 kw |

| Filling Range | ≤ 500 g | Compress air | ≥ 0.5 m³/min |

| Max Speed | ≤ 55 bags/min | Dimensions | 2300 mm*1950 mm*1560 mm |

| Models | RZ10-160E | RZ10-220E | RZ10-GS220E | RZ8-240E | RZ8-300E | RKA-825 | RZ8-S120 | RZ8-S170B | RZ10-M190 (Gusset Bag) |

RZ8-400E |

| Main Features | 10 stations, high speed | 10 stations, high speed | special for easy blocked products | widely application | widely application, wide width range | Korea Design,More advanced design with anti-collision features | double bag, high speed | double bag | Special for M type bags(gusset bags / square bag) | Big Bag with Big weight |

| Stations | 10 stations | 10 stations | 10 stations | 8 stations | 8 stations | 8 stations | 8 stations | 8 stations | 10 stations | 8 stations |

| Bag Width Range | 60-160 mm | 80-220 mm | 100-220 mm | 80-240 mm | 180-300 mm | 90-250 mm | 50-120 mm | 85-170 mm | 80-190 mm; side width ≤50mm | 240-400mm |

| Bag Length Range | 80-370 mm | 100-370 mm | 150-370 mm | 150-370 mm | 150-450 mm | 150-370 mm | 80-370 mm | 150-330 mm | 80-370 mm | 150-600mm |

| Filling Range | ≤ 500 g | ≤ 1500 g | ≤ 1000 g | ≤ 1500 g | ≤ 2500 g | ≤ 2500 g | ≤ 500 g | ≤ 1000 g | ≤ 500 g | ≤ 5000g |

| Max Speed depends on the bag and product |

≤ 100 bags/min | ≤ 60 bags/min | ≤ 45 bags/min | ≤ 60 bags/min | ≤ 50 bags/min | ≤ 60 bags/ min | ≤ 130 bags/min | ≤ 100 bags/min | ≤ 55 bags/min | ≤ 30 bags/min |

| Machine Weight | 1450 kg | 1800 kg | 1800 kg | 1500 kg | 1800 kg | 2700 kg | 2500 kg | 3000 kg | 2000 kg | 2500 kg |

| Machine Dimensions(mm) | 1840*1610*1550 | 1950*1740*1550 | 1950*1720*2420 | 1860*1520*1550 | 2080*1700*1650 | 2200*2050*2000 | 1850*2360*1550 | 2320*2060*1650 | 2260*1950*1550 | 2150*2020*1700 |

| Total Power | 3.22 kw | 3.42 kw | 9.47 kw | 3.02 kw | 3.62 kw | 4 kw | 5.41 kw | 5.41 kw | 4.12 kw | 3.62 kw |

| Driving Power | 380 V 3P 5W 50HZ (other power supply can be customized) | |||||||||

| Compress air requirement (provided by the customer) |

≥ 0.5 m³/min | ≥ 0.4 m³/min | ≥ 0.4 m³/min | ≥ 0.4 m³/min | ≥ 0.4 m³/min | ≥ 0.4 m³/min | ≥ 0.4 m³/min | ≥ 0.4 m³/min | ≥ 0.5 m³/min | ≥ 0.4 m³/min |

With over 33 years of experience in the packaging industry and 20 years of specialized focus on rotary packing machines, Rezpack has built a reputation for delivering top-notch, customized solutions. Over 3,000 customers across Europe, the US, Australia, and Asia trust Rezpack machines for their packaging needs.

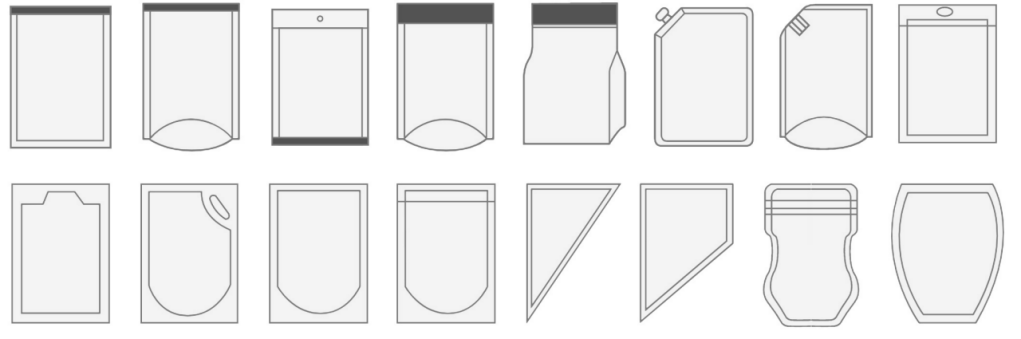

Our rotary premade pouch pick fill seal machines are tailored to suit your product and packaging requirements. Whether you’re packing granules, powders, or liquids, our machines can handle various bag types, including standup, zipper, spout, and shaped pouches. We provide customized solutions within 24 hours, taking into account your product features, bag type, size, and weight.

We’ve successfully implemented packaging solutions for a wide range of products, including grains, coffee, nuts, jerky, tea, chips, flour, spices, water, oil, and detergents. Our rotary packaging machines support multiple bag sizes, easily adjustable via touch screen, with settings saved for future use.

Before you place an order, we’ll test your products and bags to ensure the most suitable solution. Our machines can be equipped with specialized features, such as anti-blocking devices for solids and foam prevention for detergents, to ensure optimal performance. Additional features like nitrogen filling or vacuum sealing can also be integrated.

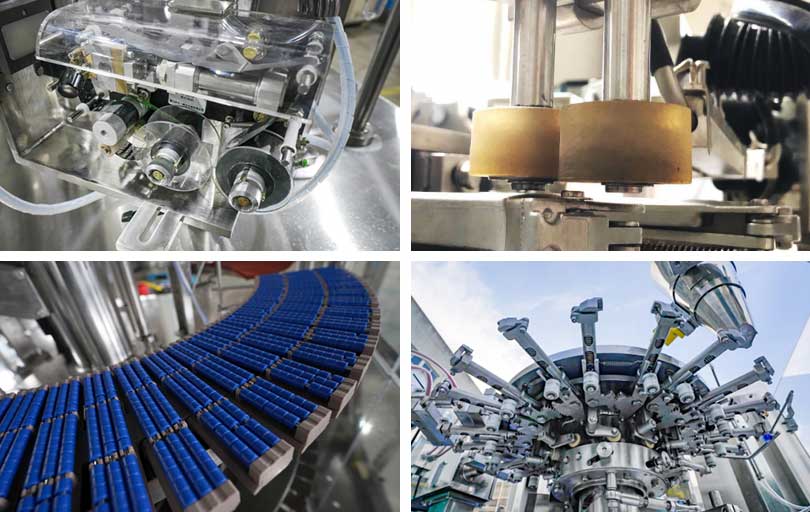

We use high-quality components, such as grooved cams, to ensure stability and longevity. Each machine undergoes thorough testing, both before and after assembly, ensuring smooth operation before delivery. Our team offers on-site installation support and quick problem-solving assistance, making Rezpack your trusted partner in rotary packing.

Key Advantages:

◎ Adjustable bag clamps via touch screen

◎ No-fill/no-seal alarm system

◎ Safety guards with switches and alarms

◎ Hygienic construction with SUS304 stainless steel contact parts

◎ Oil-free vacuum pump to prevent contamination

Choose Rezpack for reliable, high-performance rotary sealing machines.

And for some special bags, we also will have some requirements:

◎ Zipper/detachable/self-sealing bag packaging -- the distance between the zipper and the bag opening top must be at least 25-35mm.

◎ Clasp bag packaging -- the bag opening width is within 50mm. If the bag opening is too small and the product cannot be fully filled, packaging cannot be done.

◎ Spout bag packaging -- One is filling from the bag top, so the spout is on the bag corner, and not over the bag top and the side. If filling from the spout, the spout must be designed to hanging type.

◎ Tray bag packaging -- the tray is placed inside the bag, and the length of the tray is at least 30mm below the bag opening.

◎ Gusset bag packaging -- the guesst side width cannot over 50mm, and the packing weight cannot be over than 500g.

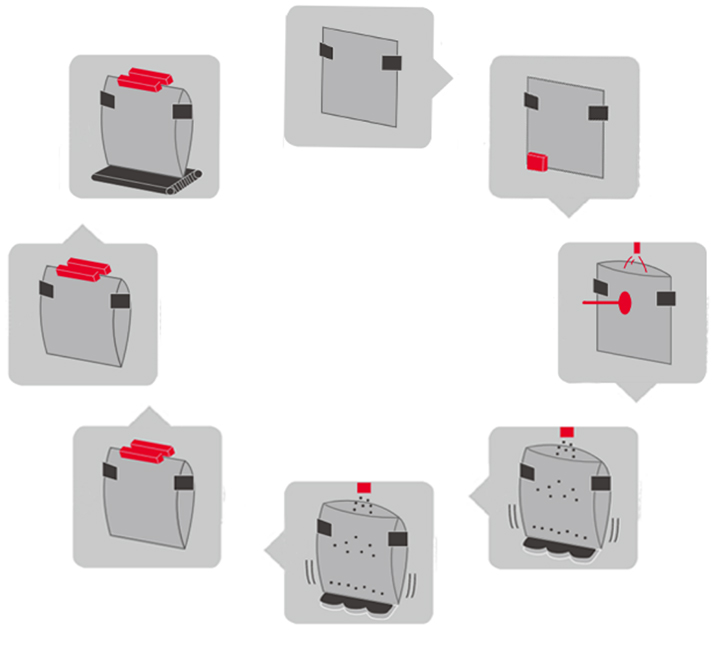

◎ Giving bags -- Send many small bags or pouches into the bag storage. Our main bag storage can move up and down, making it very easy to send the bags in when it moves down. When it moves up, a mechanical arm with two vacuum caps picks up the bag and transfers it to the mechanical gripper on the rotating table.

◎ Date printing -- Configure different types of coding machines according to actual production and packaging needs to print dates and batch numbers on the packaging bags.

◎ Bag opening -- As the suction cup opens the packaging bag mouth, air is blown out from the upper nozzle to open the bottom of the packaging bag. The packaging bag support plate is inserted into the packaging bag mouth, and the packaging bag enters the next station. After inserting the packaging bag support plate into the packaging bag mouth, check whether there is a packaging bag and whether the packaging bag mouth is open. If there is no packaging bag or the opening of the packaging bag is not open, the next station will not be fed.

◎ Filling & Consolidate 1 -- Configure different feeders at this station according to different packaging materials to complete automatic or semi-automatic feeding.

◎ Filling & Consolidate 2 -- Configure different feeders at this station according to different packaging materials to complete automatic or semi-automatic feeding.

◎ Buffer (or others)

◎ Heat sealing 1 -- Seal the small bag or bag mouth with several heat-sealing strips. The sealing mode can be selected as a mesh or a straight line.

◎ Heat sealing 2 -- Use several cold presses to make the seal stable and prevent wrinkles, and then automatically output the finished product.

At our company, we prioritize quality and reliability, which is why our rotary premade pouch pick fill seal machine is made from high-quality materials and components. This ensures that the machine performs consistently and reliably, with minimal downtime and maintenance. And all functions of the machine are customized according to your real product.

If you're looking for a reliable, efficient, and cost-effective solution for your automatic weighing and filling needs, look no further than the rotary premade pouch pick fill seal machine. Contact us today to learn more about our product and how it can benefit your business.