| Bag Width Range | 80-240 mm | Weight | 1500 kg |

| Bag Length Range | 150-370 mm | Total power | 3.02 kw |

| Filling weight | ≤ 1500g | Compress air | ≥ 0.4 m³/min |

| Max Speed | ≤ 60 bags/min | Dimensions | 1860 mm*1520 mm*1550 mm |

Vacuum-packed food typically lasts 3–5 times longer than conventionally stored food, depending on the type of food, storage conditions, and packaging quality. By removing oxygen and sealing out contaminants, vacuum packaging significantly slows spoilage, oxidation, and microbial growth.

Oxygen and moisture are primary culprits in food degradation. Vacuum packaging eliminates up to 99% of oxygen from the package, inhibiting aerobic bacteria and mold while preserving texture, flavor, and nutrients. For example:

*Meat and fish: Lasts 6–12 months (frozen) vs. 3–6 months in standard packaging.

*Cheese: Up to 8 months vs. 1–2 weeks when exposed to air.

*Dry goods (e.g., coffee, nuts): 12–24 months without staleness or rancidity.

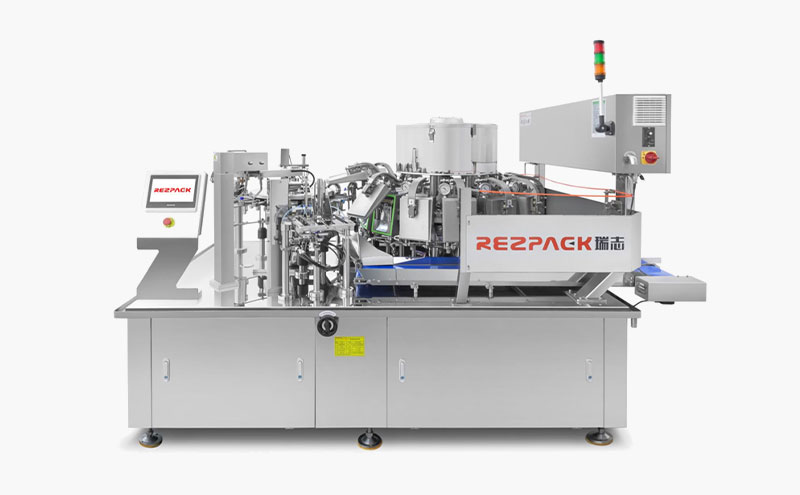

While home vacuum sealers work for small-scale use, commercial-grade results demand precision and speed. This is where innovations like rotary vacuum packaging machines shine. Designed for high-volume production, these machines automate the entire process—evacuating air, sealing packages, and cutting them in a single motion—ensuring airtight protection for every item. Their reliability minimizes human error, maintains uniform seal quality, and complies with strict food safety standards. For producers, this technology isn’t just about efficiency; it’s a critical tool for delivering vacuum-packed foods that truly meet their extended shelf-life potential.

Even with vacuum packaging, shelf life depends on:

*Initial food quality: Fresher ingredients last longer.

*Storage temperature: Refrigeration or freezing further extends preservation.

*Packaging material: High-barrier films block oxygen and moisture effectively.

*Always label packages with dates.

*Store vacuum-sealed items in cool, dark environments.

*Inspect seals for leaks before long-term storage.

Vacuum packaging revolutionizes food preservation, but its effectiveness hinges on proper execution. For industries, advanced tools like rotary vacuum machines ensure scalability and consistency, bridging the gap between laboratory-perfect conditions and real-world production. Whether you’re a home user or a business, understanding these principles helps maximize the lifespan of vacuum-packed foods—safeguarding flavor, nutrition, and safety far beyond traditional methods.

| Bag Width Range | 80-240 mm | Weight | 1500 kg |

| Bag Length Range | 150-370 mm | Total power | 3.02 kw |

| Filling weight | ≤ 1500g | Compress air | ≥ 0.4 m³/min |

| Max Speed | ≤ 60 bags/min | Dimensions | 1860 mm*1520 mm*1550 mm |

| Bag Width Range | 180-300 mm | Weight | 1800 kg |

| Bag Length Range | 150-450 mm | Total power | 3.62 kw |

| Filling weight | ≤ 2500 g | Compress air | ≥ 0.4 m³/min |

| Max Speed | ≤ 50 bags/min | Dimensions | 2080 mm*1720 mm*1650mm |

| Bag Width Range | 270-400 mm | Weight | 2500 kg |

| Bag Length Range | 150-600 mm | Total power | 3.62 kw |

| Filling Range | ≤ 5000g | Compress air | ≥ 0.4 m³/min |

| Max Speed | ≤ 30 bags/min | Dimensions | 2150 mm*2020 mm*1700 mm |